Direct Metal Laser Sintering

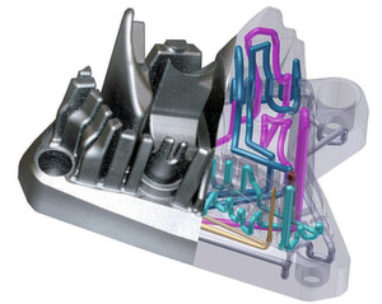

DMLS process enables the fabrication of fully dense 3D Structures by selective melting of micro-sized metal powder using a high-intensity laser beam.Due to its ability to form fully dense structures, the mechanical properties are equivalent to those achieved by the use of conventional manufacturing methodology.